Oil-Filled Transformer

Advantages:

Effective heat dissipation, robust insulation, dependable operation, and extended service life are characteristics of oil-immersed transformers. They are extensively utilized in power systems, commercial buildings, mining and industrial operations, and new energy power plants due to their exceptional overload performance, superior load capacity, and low maintenance costs.

Oil-immersed transformer is a basic power distribution equipment, designed to supply a stable, efficient, and safe transformation of voltage. Unlike dry type, it utilizes insulating oil as an electrical insulation and cooling medium. The heat is easily dissipated through the oil, windings are covered, and the transformer works well in the long run.

With effective thermal conductivity, good insulation, and high overload capability, the oil-immersed transformer is impressive in its reliability and economy. Low noise during its operation, low maintenance, and stability in operation even under harsh conditions make it a product in its own league.

Heavily employed in power systems, mines and industries, business centers, and wind and solar power stations, oil-immersed transformers are indispensible in providing uninterrupted and efficient power supply. Owing to their proven reliability and flexibility, oil-immersed transformers are the ideal choice in modern infrastructure developments.

Features & Benefits of Oil-Immersed Transformer

Oil-immersed transformers are provided with advanced insulation and cooling systems in order to enable steady and long-lasting operation. Among their most significant features are their high heat dissipation efficacy, achieved by insulated oil circulation that, in addition to preventing overheating, insulates inner windings. This provides a longer time of operation as well as higher reliability.

The other significant advantage is their good load-carrying ability and superior overload capability, enabling the transformer to function within safety limits with changes in the loading conditions without a loss in stability. Their good insulation characteristics deliver superior protection againstfaults, and the sealed type minimizes the possibility of moisture entry and adds stability.

Additionally, oil-immersed transformers have low maintenance levels and are economically efficient, thereby being highly cost-effective in the long run. They are low in noise levels, and that is quite beneficial in a business district or a city.

In general, due to the inclusion of efficiency, reliability, and durability, oil-immersed transformers are a preferable selection in power distribution systems in industries and power industries.

Oil-Immersed Transformer Application Scenes

Oil-immersed transformers are popular in most industries because they are dependable in their operation and are flexible in application. In power transmission and distribution systems, they are essential in raising or lowering the voltage, thereby facilitating the transmission and distribution in a safe and efficient manner, and reaching residential, commercial, and industries.

These are used in mines and industries by providing steady power during continuous and heavy-duty usage. Their ability and endurance in handling overload make them particularly suitable in rough conditions.

Oil-immersed transformers in business centers and skyscrapers provide a secure power supply to lights, lifts, air-conditioning units, and auxiliary equipment, and ensure effective day-to-day operations.

They are increasingly employed in renewable power systems, such as wind power stations and solar farms, in which efficient and predictable energy conversion is required in a bid to attain sustained power generation.

With their broad application coverage, oil-immersed transformers have established themselves as a pillar in the development of robust and effective energy infrastructures globally.

FAQ – Oil-Immersed Transformer

Q1: What is the main characteristic difference between a dry-type and an oil-immersed transformer?

A1: The insulating oil in an oil-immersed transformer provides insulation and cooling, and a dry-type transformer either makes use of air or resin. Oil-immersed transformers tend to have a greater capacity and a longer lifespan.

Q2: How long is the service life of an oil-immersed transformer?

A2: Through careful maintenance and operation, an oil-immersed transformer is capable of lasting over 25–30 years, depending on conditions and environments of use.

Q3: Can oil-immersed transformers be used?

A3: Yes. They are designed with sealed tanks to ensure no leakage of oil, and their sophisticated insulation systems allow for safe and stable operations at different loads.

Q4: What maintenance is required on oil-immersed transformers?

A4: Regular maintenance involves oil quality checking, monitoring operating temperature, and seal and connection checking. These are effective in providing reliable operation.

Q5: Where are oil-immersed transformers usually applied?

A5: They are used in power distribution networks, industries, business centers, and renewable power plants, e.g., solar and wind power stations.

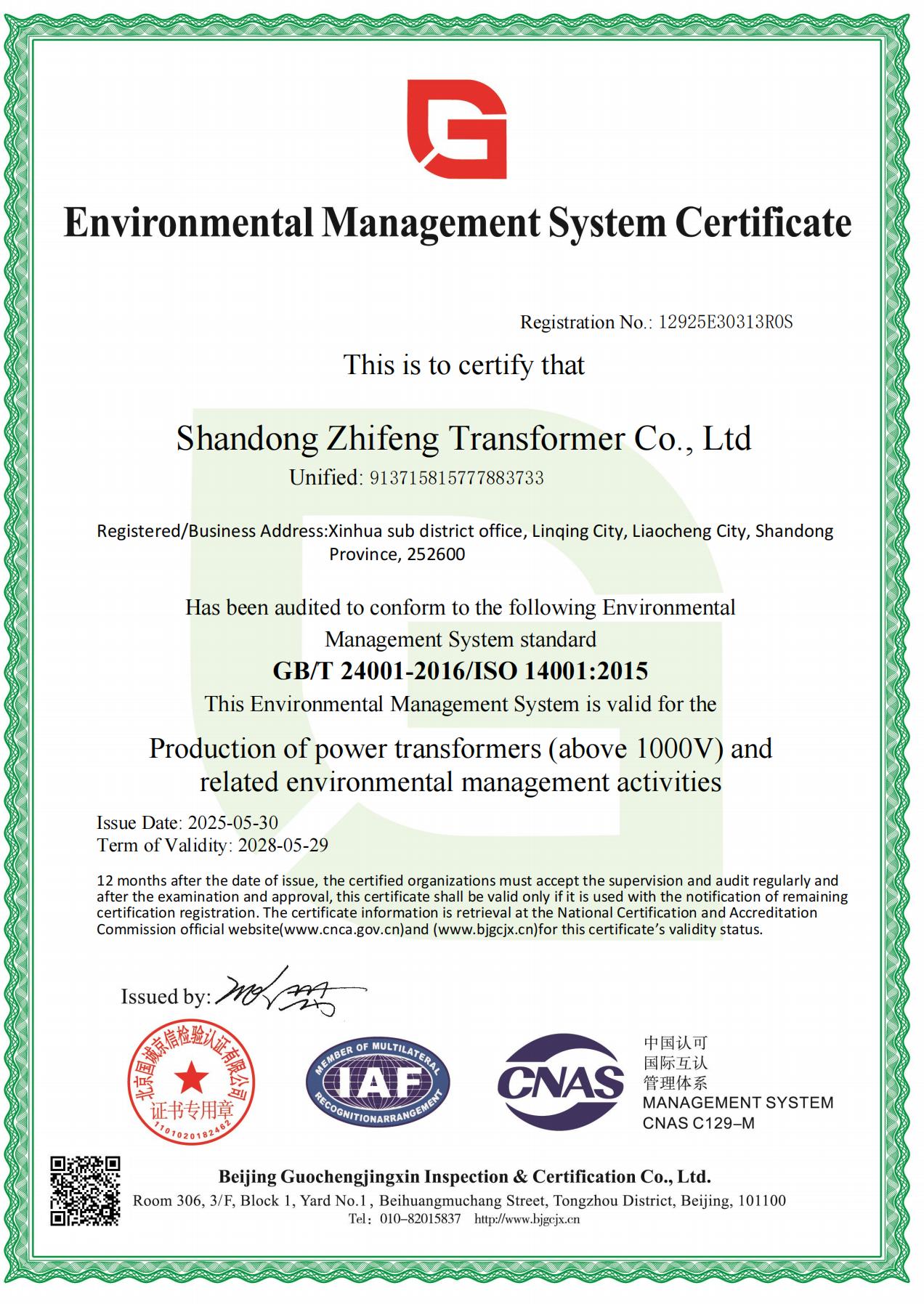

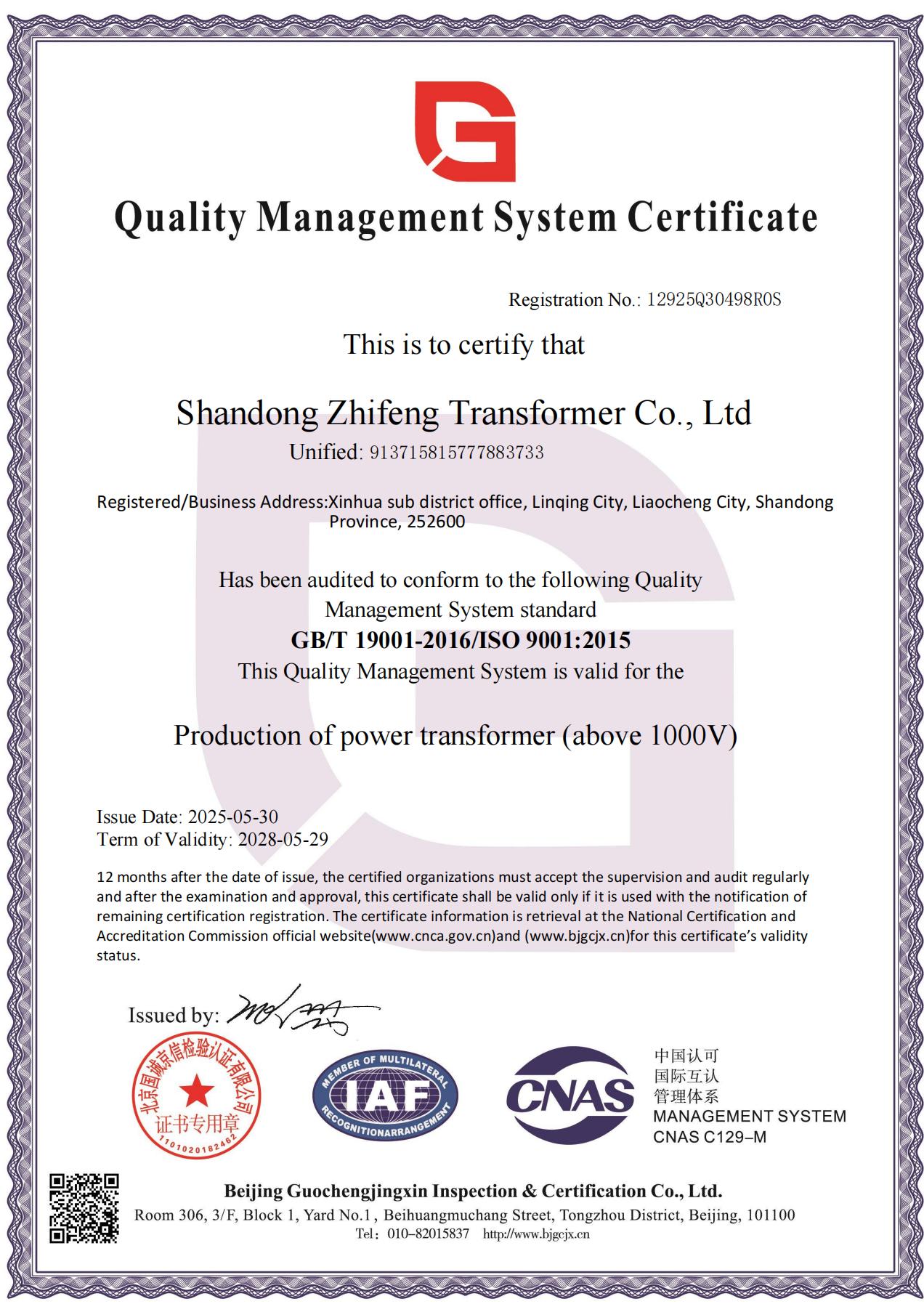

Certificate:

Submitted successfully

We will contact you as soon as possible