Powering Your Business: A Deep Dive into Oil-Immersed and Dry-Type Transformers

The transformer is a vital piece of equipment in the field of electrical power distribution. It ensures that factories, commercial buildings, and data centers can safely and effectively use grid electricity by silently and effectively stepping voltage up or down. One question that comes up time and time again when choosing the best transformer for your application is one that industry experts frequently search for: What distinguishes dry-type transformers from oil-immersed transformers?

Knowing the difference affects safety, cost, dependability, and operational efficiency, making it more than just an academic exercise. At [Your Company Name], we think that educating our clients is empowering. To help you choose the best option for your power requirements, this article will offer a thorough comparison.

The Fundamental Distinction: Insulation and Cooling

The cooling and insulation strategies used by these two transformer types represent the most significant distinction between them.

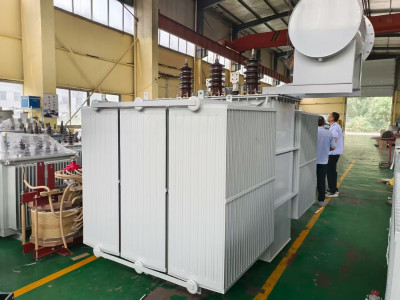

A specialized dielectric (insulating) oil serves as both an insulating and cooling medium in an oil-immersed transformer. This oil, which circulates naturally or through pumps, completely submerges the core and windings, removing heat from the core and distributing it through external radiators.

As the name suggests, a dry-type transformer doesn't use any liquid. Instead, it uses high-quality solid insulation materials, like cast resin or vacuum pressure-encapsulated (VPE) epoxy resin, to protect its windings and relies on ambient air for cooling.

A series of additional variations in their use, setup, and upkeep follow from this fundamental distinction.

Principal Benefits:

Superior Cooling and Overload Capacity: These transformers can withstand higher overloads for brief periods of time without suffering damage because the dielectric oil is a superior heat conductor. They are very sturdy as a result.

High Efficiency and Long Lifespan: Oil-immersed transformers are designed to last for decades, frequently 25–30 years or longer with proper maintenance, and are generally more efficient at higher ratings.

Cost-Effectiveness for High Power: Compared to their dry-type counterparts, they are usually more cost-effective for large-scale power requirements (usually above 10 MVA).

Conclusion: Partnering for the Right Power Solution

The debate between oil-immersed transformers and dry-type transformers has no single winner. The right choice is entirely dependent on the unique demands of your electrical infrastructure. By understanding the key differences in cooling, safety, application, and cost, you can make an informed decision that ensures reliability, safety, and operational efficiency for years to come.

At [Your Company Name], we specialize in both technologies. Our team of experts is ready to guide you through this critical selection process, providing high-quality, reliable oil-immersed transformers for rugged outdoor duty and advanced dry-type solutions for your most sensitive indoor environments. Contact us today for a consultation, and let us help you power your future with confidence.