Grounding transformer

Grounding transformer

1. Iron core

In order to improve the performance of the iron core, high-quality, low consumption, grain oriented cold-rolled silicon steel sheets are used, and multi-stage oblique lap joints are adopted on the core column and iron yoke. During assembly, the entire iron core is compressed with uniform pressure, and the transformer iron core should not loosen due to transportation and operation vibrations.

2. Oil storage tank

The connecting pipe between the oil storage tank and the transformer oil tank should be unobstructed. In order to facilitate the collection of gas inside the gas relay, it is required that the connecting pipes of the riser, transformer and oil storage tank, and the horizontal plane have a rising slope of about 1.5 °. Transformers must not have any gas storage phenomenon.

3. Winding

The winding should be tightly wound, and insulation should be strengthened at the positions and ends. The wrapping should be correct, and the bends in the line segment should be leveled without any climbing (scissor mouth) phenomenon. The coil tap should be securely tied. There should be at least four sections of winding at the beginning and end to strengthen the mechanical strength, and there should be horizontal wrapping to prevent the winding from loosening and rebounding.

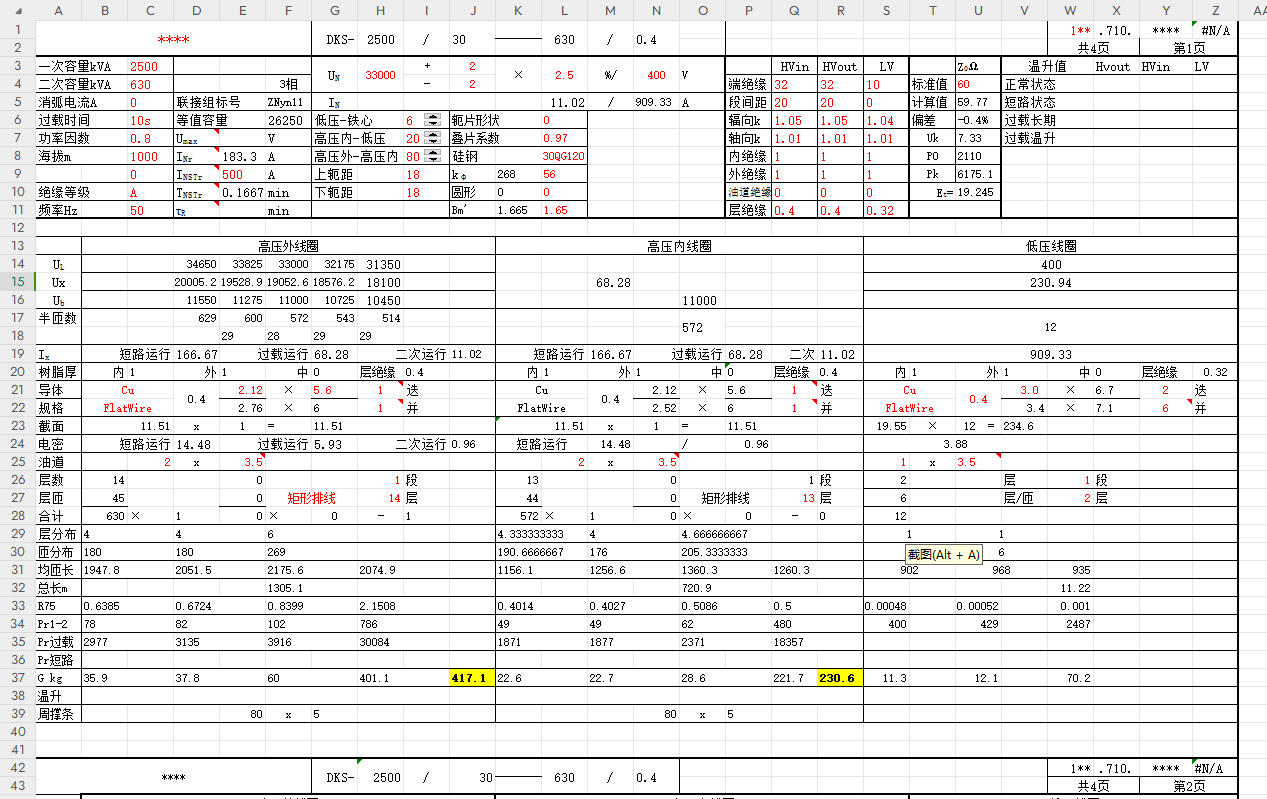

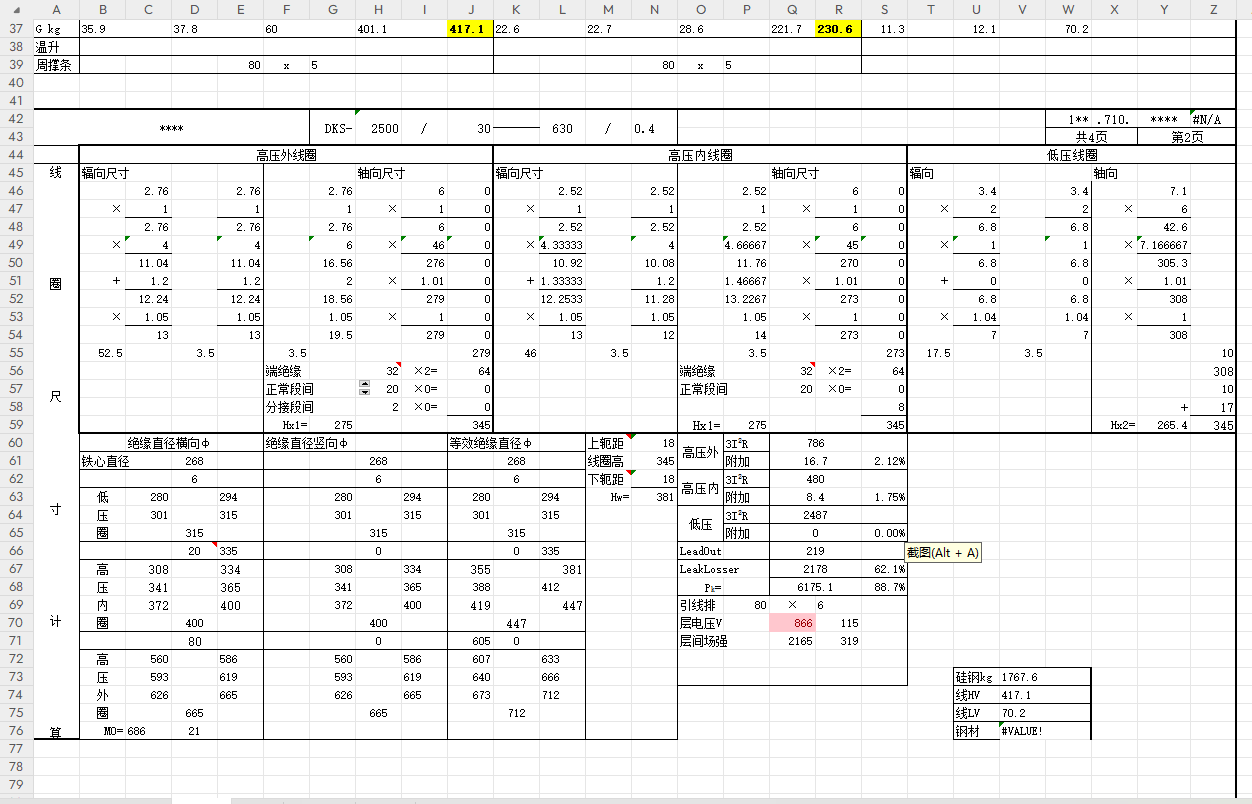

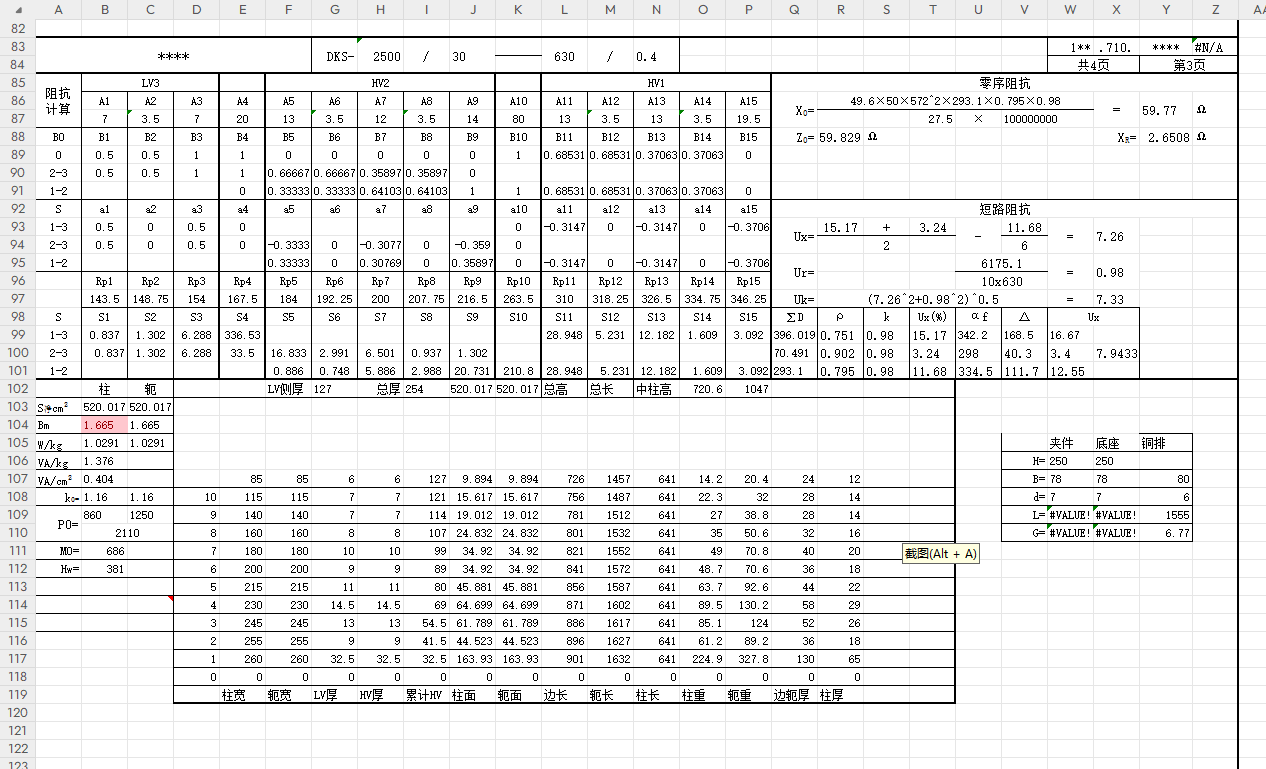

Grounding transformer Parameter Table

Submitted successfully

We will contact you as soon as possible